The factory, established in 1996 and originally known as Ruili Machinery Factory, has a well-operated history of nearly 30 years. Specializing in manufacturing automatic sawing machines and multi-blade saws, the company has earned a reputation for producing high-quality, reliable equipment that meets the needs of professional woodworkers and manufacturing businesses.

The introduction of the CNC Beam Saw represents a significant milestone for the company, as it demonstrates their commitment to innovation and continuous improvement in the field of woodworking machinery. With a focus on customer satisfaction and technological advancement, the company has invested significant resources in research and development to bring this cutting-edge product to market.

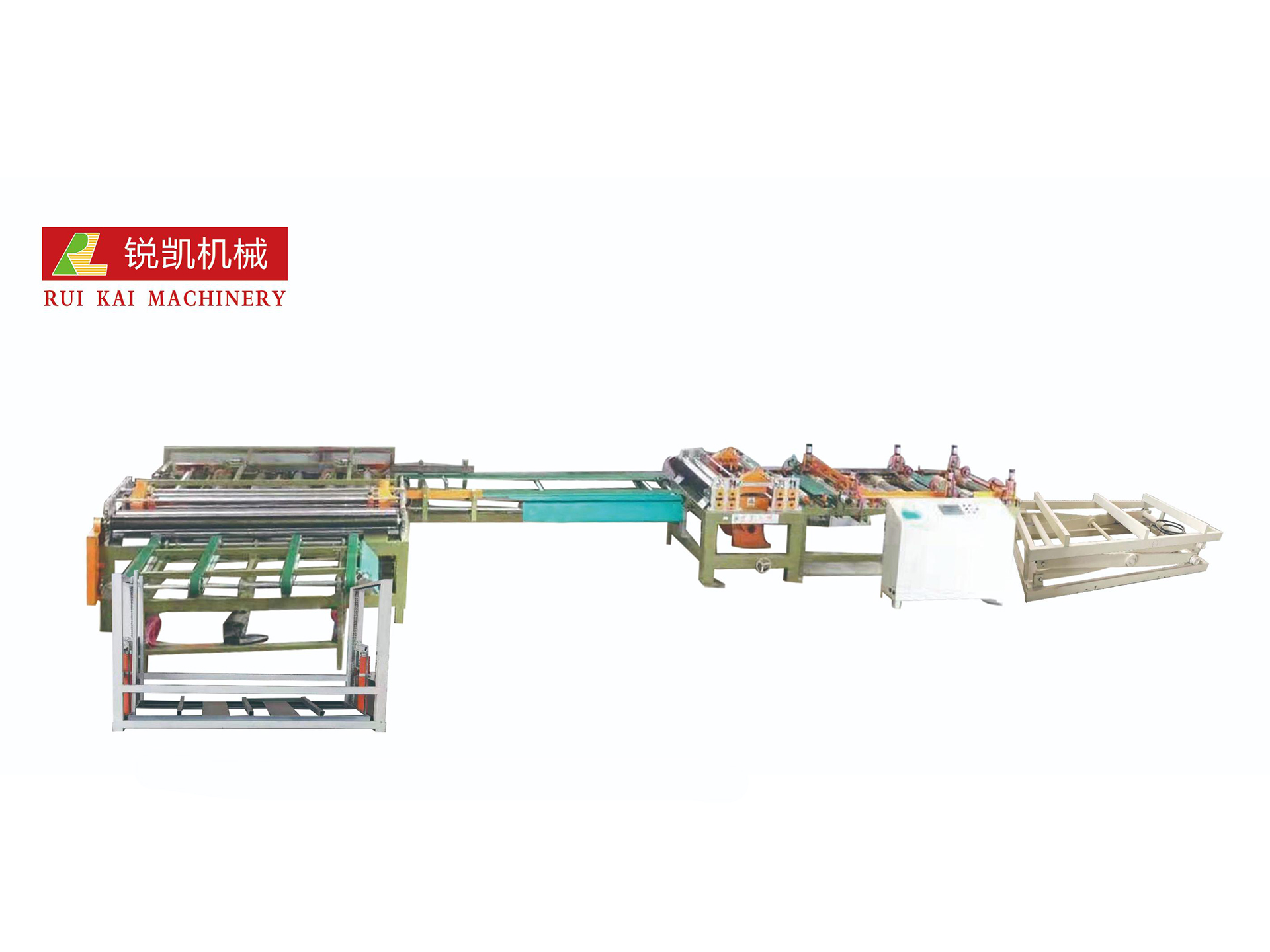

The CNC Beam Saw is designed to provide unrivaled accuracy and efficiency in cutting large panels and beams. Equipped with advanced computer numerical control (CNC) technology, the machine offers precise control over the cutting process, ensuring that every piece is accurately cut to the desired dimensions. This level of precision is essential for woodworking projects that require tight tolerances and exact measurements.

In addition to its precision cutting capabilities, the CNC Beam Saw is also designed for maximum efficiency and productivity. With its automated operation and high-speed cutting capabilities, the machine can significantly reduce production times and labor costs, leading to improved overall profitability for woodworking businesses.

Furthermore, the CNC Beam Saw is equipped with a range of advanced features and capabilities to enhance its performance and versatility. These include automatic material loading and unloading, adjustable cutting parameters, and compatibility with a wide range of materials, such as wood, plastic, and composite panels. This versatility makes the machine suitable for a diverse range of woodworking applications, from furniture manufacturing to cabinetry and construction.

The introduction of the CNC Beam Saw is expected to have a profound impact on the woodworking industry, as it represents a significant leap forward in terms of technological innovation and manufacturing capabilities. By offering woodworkers and manufacturers access to this cutting-edge technology, the company is empowering them to take on more complex projects and deliver higher-quality results for their clients.

As a company, the commitment to quality and innovation is evident in the development of the CNC Beam Saw. With a team of experienced engineers and technicians, the company has worked tirelessly to ensure that the machine meets the highest standards of performance, reliability, and safety. Rigorous testing and quality control measures have been implemented throughout the manufacturing process to guarantee that every CNC Beam Saw that leaves the factory is ready to exceed customer expectations.

Looking ahead, the company is poised to continue its legacy of excellence and innovation in the woodworking machinery industry. With a strong foundation built on decades of experience and a dedication to meeting the evolving needs of woodworkers and manufacturers, the company is well-positioned to remain a leader in the market for years to come.

In conclusion, the introduction of the CNC Beam Saw represents a significant milestone for the woodworking machinery industry. With its advanced technology, precision cutting capabilities, and focus on efficiency and productivity, the machine is set to revolutionize the way woodworking projects are executed. As the company continues to push the boundaries of innovation, customers can expect to see even more groundbreaking developments that will further elevate the standards of the woodworking industry.